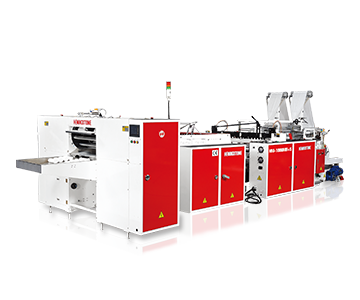

High Speed Fully Automatic Bottom Sealing Machine for coreless Bags on Rolls with Photo Cell

Model: HM-1000MR

FINISHED PRODUCTS

Vegetable Bag

Star Seal Bag

Garbage Bag

Table Cloth

FEATURES

High speed, perforated & printed bag on roll making machine employs a synchronic transmission using a 4 servo motor control system to provide stable production speeds.

Fully automatic electrical control system.

Newly designed curved type sealing knife system work with bottom sealed or double sealed bags thanks to independent temperature control-no need to change sealing knife.

Sealing and perforation knives move simultaneously.

Average production speed of printed bags and plain bags is 120 m/min (240 cycles/min.)

Produces star seal bags, garbage bags, vegetable bags, table cloths, and laundry bags.

Suitable materials include HDPE, LDPE, LLDPE and recycled material.

There is one photo cell on this machine for the manufacture of one line printed bags.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-1000MR | ||

| Bag Sealing Size | Film Unwind Width(mm) | 900 x 1, 400 x 2 | |

| Film Diameter(mm) | 800 | ||

| Bag Size (mm) |

Width |

900 x 1, 400 x 2 | |

| Length | 150~2000 | ||

| Production Speed pcs/min | 200 | ||

| Lines Speed |

Without Core(m) |

120 | |

| With Core(m) | - | ||

| Thickness of Film (Total mm) | 0.02~0.2 | ||

| Speed for Changing the Roll | 7 | ||

| Production of Rolls | Without Core |

Roll Width(mm) |

580 x 1, 260 x 2 |

| Roll Diameter(mm) | 170 | ||

| With Core |

Roll Width(mm) |

- | |

| Roll Diameter(mm) | - | ||

| Machine Dimensions | L(m) | 6.5 | |

| W(m) | 2.43 | ||

| H(m) | 2 | ||

| Machine Weight(kg) | 2500 | ||

| Air Compressor(not included) | 5 | ||

Relative Products

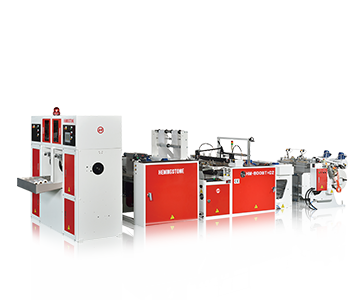

2 Lines Bottom Sealing Machine for Bags On Rolls with Core for Star Sealing Bag, Vegetable Bag and bottom Sealing with Side Gusset Bag

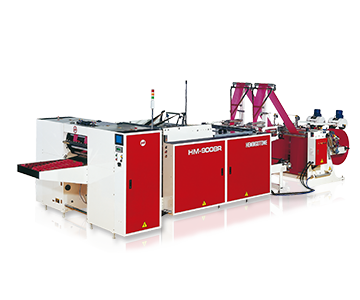

High Speed Fully Automatic Bottom Sealing Machine for Coreless Bags on Roll

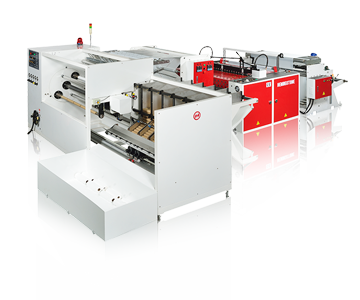

High Speed 5 Line Bottom Sealing Bag on Roll Making Machine with Hot Slitting Unit & Photo Cell

HM-990MR+BC

High Speed Bottom Sealing Machine for Bag-on-roll with or without Core With Photo Cell

High Speed Bottom Sealing and Double Sealing Bag Machine for Coreless Bag on Roll with S Type Perforation Unit & Photo Cell

High Speed Bottom Sealing Machine for Bag-on-roll with or without Core with Hot Slitting Unit & Photo Cell

High Speed 5 Line Bottom Sealing Bag on Roll Making Machine With Hot Slitting Unit, Photo Cell & Auto Rewinding Unit for Auto Paper Core Changing