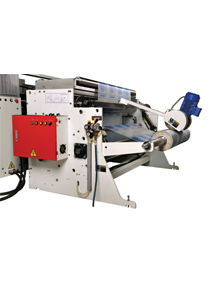

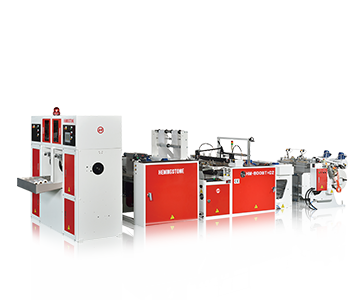

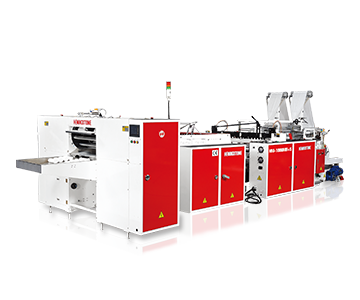

High Speed 5 Line Bottom Sealing Bag on Roll Making Machine With Hot Slitting Unit, Photo Cell & Auto Rewinding Unit for Auto Paper Core Changing

Model: HM-1250MR + BP5A

FINISHED PRODUCTS

5-Lines Bottom Sealing Bag by Hot-Slitting

FEATURES

This multi-line bag making machine is especially designed for mass production of bottom sealed bag on roll. Bottom sealed bags are largely used as vegetable and fruit bags.

Function: Jumbo film is side sealed or bottom sealed then perforated. The perforated film goes through the multiŌĆōline hot slitting system to be slit and hot sealed into bags. Perforated bags are wound automatically. The most distinguishing feature is the non-stop bottom sealing device. Bottom sealing is performed using the principal of rocking system so sealing and perforating are carried out simultaneously.

Therefore simultaneous perforating and sealing allow the machine to run without stopping.

Benefits: The automatic winding system allows for mass production while greatly reducing labor requirements. Very easy to operate the machine with an exceptional servo drive system. This machine is a great choice for high speed mass production printed and non-printed bags.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-1250MR+BP5 | HM-1250MR+BP5A | |

| Film Width (Unwind)(mm) | 1200 | 1200 | |

| Film Dia.(mm) | 800 | 800 | |

| Bag Size | Width(mm) | 100-1200 | 100-1200 |

| Length(mm) | 250-2000 | 250-2000 | |

| Max. Production Speed(pcs/min) | 200 x 5 = 1000 | 200 x 5 = 1000 | |

| Line Speed (m/min) | 120 | 120 | |

| Thickness of Film(mm) | 0.01-0.08 | 0.01-0.08 | |

| Speed for Changing The Roll/max | 4 | 2 | |

| Roll size | width(mm) | 100-1200 | 100-1200 |

| Length(mm) | 300 | 200 | |

| Power Required (kw) | 17 | 18 | |

| Machine Dimensions | L(m) | 7.2 | 7.2 |

| W(m) | 2.8 | 4.1 | |

| H(m) | 2.1 | 1.8 | |

| Machine Weight(kg) | 3000 | 3500 | |

| Air Compressor(not included) | 5 | 5 | |

Relative Products

2 Lines Bottom Sealing Machine for Bags On Rolls with Core for Star Sealing Bag, Vegetable Bag and bottom Sealing with Side Gusset Bag

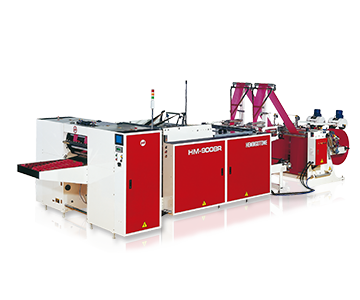

High Speed Fully Automatic Bottom Sealing Machine for Coreless Bags on Roll

High Speed 5 Line Bottom Sealing Bag on Roll Making Machine with Hot Slitting Unit & Photo Cell

HM-990MR+BC

High Speed Fully Automatic Bottom Sealing Machine for coreless Bags on Rolls with Photo Cell

High Speed Bottom Sealing Machine for Bag-on-roll with or without Core With Photo Cell

High Speed Bottom Sealing and Double Sealing Bag Machine for Coreless Bag on Roll with S Type Perforation Unit & Photo Cell

High Speed Bottom Sealing Machine for Bag-on-roll with or without Core with Hot Slitting Unit & Photo Cell