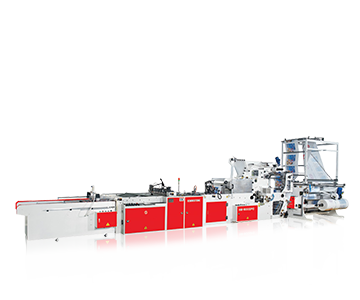

Super High Speed Fully Automatic Inside Glue Patch Handle Carrier Bag Making Machine with Wicketer

Model: HM-800GPW

FINISHED PRODUCTS

Patch Handle Bag

FEATURES

It's integrated with the high technology.

With design of automation, it's fully automatic for production.

With varied automatic alarm.

Optional device for die cut handle bags.

Optional device for single sheet.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-800GPW | |

| Bag Sealing Size | Width | 200~600 |

| Length | 300~660 | |

| Bottom Gusseting | 30~75 | |

| Master Film Unwind Width(mm) | 1600 | |

| Max. production Speed (cycles/min) | 150~220 | |

| Line Speed (m/min) | Max. 90 | |

| Thickness of Film(mm) | 0.06~0.1 | |

| Patch film roll width(mm) | 140 | |

| Patch film roll diameter(mm) | 600 | |

| Heaters (kw) |

1.8KW x 1 0.8KW x 5 |

|

| Power required | 12.0KW | |

| Machine Dimensions | L(m) | 13 |

| W(m) | 2.45 | |

| H(m) | 2.75 | |

| Machine Weight(kg) | 4000 | |

| Air Compressor(not included)(hp) | 10 | |