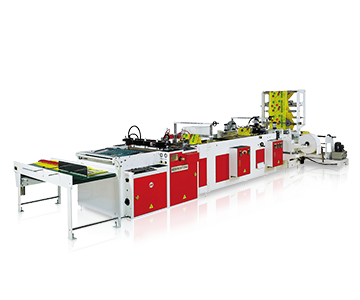

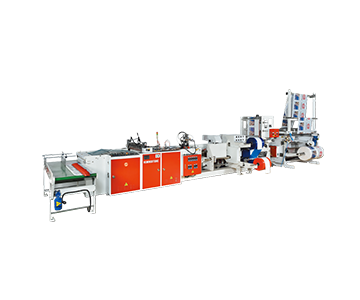

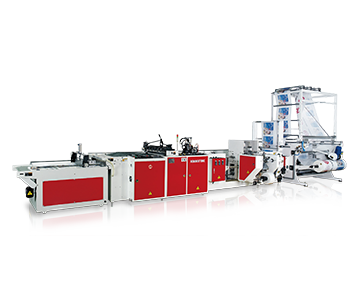

High speed SOFT LOOP & DIE CUT HANDLE bag making machine

Model: HM-830MF

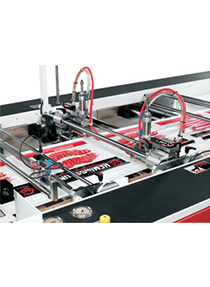

FINISHED PRODUCTS

Soft Loop Handle Bag

Die Cut Handle Bag

FEATURES

This is the cutting edge design super high-speed soft loop handle & die cut handle bag making machine that we have researched and developed over a decade.

The designs of the entire production processes are the results of brainstorming and nonstop improvement. This machine will highly enhances production efficiency, reduces the production cost and allows the buyer to gain a significant margin of profit in the market.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-830MF | HM-1030MF | |

| Bag Size | width | 250~650mm | 250~650mm |

| Length | 250~650mm | 250~850mm | |

| Top Folding | Max.75mm | Max.75mm | |

| Bottom Gusseting | up to 65mm | up to 65mm | |

| Max. production Speed (cycles/min) | 130pcs | 120pcs | |

| Thickness of Film (mm) | 0.045~0.09 | 0.045~0.09 | |

| Heaters (kW) |

2.1kW x 1 0.6kW x 2 0.4kW x 6 |

3.1kW x 1 0.6kW x 2 0.4kW x 6 |

|

| Power Required (kW) | 10 | 11 | |

| Machine Dimensions | L(m) | 8.2 | 8.2 |

| W(m) | 2.3 | 2.5 | |

| H(m) |

2.1 |

2.1 |

|

| Machine weight (kg) | 3800 | 4200 | |

| Gross Weight (kg) | 4800 | 5200 | |

| Air Compressor (not included)(hp) | 7.5 | 7.5 | |