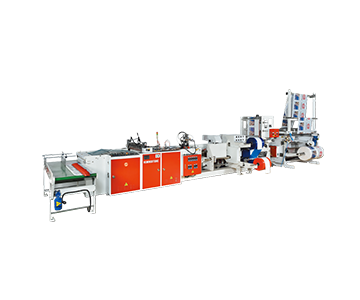

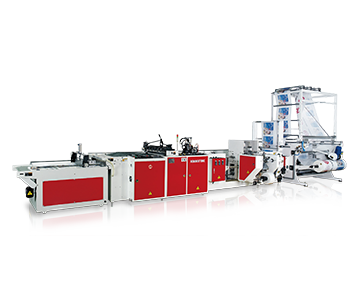

Universal plastic SHOPPING BAG making machine

Model: HM-810SFP-SV/1000SFP-SV/HM-1250SFP-SV

FINISHED PRODUCTS

Soft Loop Handle Bag

Poly Draw Bag

Die Cut Handle Bag

Patch Handle Bag

FEATURES

With soft loop handle bag

With patch handle bag

With poly draw handle bag

With die cut handle bag

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-810SFP-SV | HM-1000SFP-SV | HM-1250SFP-SV | |

| Bag Size(mm) |

Width (Each Line) |

250-650mm | 250-650mm | 250-650mm |

| Length | 250-650mm | 250-900mm | 250-1050mm | |

| Top Folding | Max.75mm | Max.75mm | Max.75mm | |

| Bottom Gusseting | up to 65mm | up to 65mm | up to 65mm | |

| Max. Production Speed cycles/min |

Soft handle 55 Patch 65 Poly Draw 65 Die Cut 75 |

|||

| Tickness of Film(mm) | 0.045-0.09 | 0.045-0.09 | 0.045-0.09 | |

| Heaters |

1.8KWx1 0.4KWx6 |

1.8KWx1/0.8KWx2/ 0.4KWx6 |

2.2KWx1/0.8KWx2/ 0.4KWx6 |

|

| Power Required | 8.5KW | 10KW | 12KW | |

| Machine Dimensions | L(M) | 7.6 | 7.6 | 7.6 |

| W(M) | 3.0 | 3.2 | 3.45 | |

| H(M) | 1.85 | 1.85 | 1.85 | |

| Machine Weight | 3,500kg | 4,200kg | 5000kg | |

| Air Compressor (not included) | 5HP | 5HP | 5HP | |