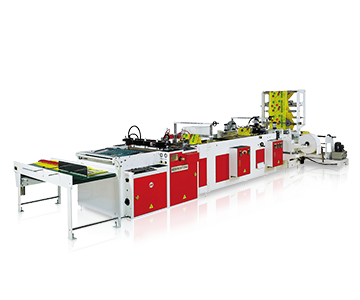

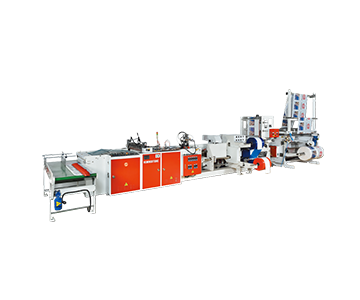

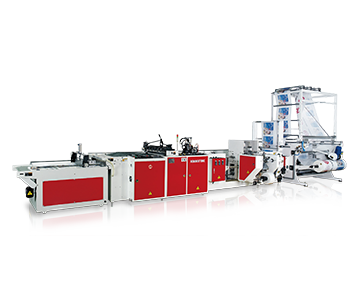

High speed SOFT LOOP, PATCH & DIE CUT plastic bag making machine

Model: HM-830MFP/ 1030MFP

FINISHED PRODUCTS

Soft Loop Handle Bag

Die Cut Handle Bag

Patch Handle Bag

FEATURES

This is a high speed and multi-function machine combining HM-830MF, high speed soft loop handle bag making machine and HM-830MP, high speed patch handle bag making machine. It is the best choice for increased capacity and space-saving benefits.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-830MFP | HM-1030MFP | |

| Bag Size | width | 250~650mm | 250~650mm |

| Length | 250~650mm | 250~850mm | |

| Top Folding | Max.75mm | Max.75mm | |

| Bottom Gusseting | up to 65mm | up to 65mm | |

| Max. production Speed (cycles/min) |

Patch 150 pcs Soft handle 120 pcs Die cut 150 pcs |

Patch 150 pcs Soft handle 120 pcs Die cut 150 pcs |

|

| Thickness of Film (mm) | 0.045~0.09 | 0.045~0.09 | |

| Heaters (kW) |

3kW x 1 0.3kW x 6 0.4kW x 6 |

4kW x 1 0.3kW x 6 0.4kW x 6 |

|

| Power Required (kW) | 15 | 16 | |

| Machine Dimensions | L(m) | 9.8 | 9.8 |

| W(m) | 3.2 | 3.4 | |

| H(m) |

1.85 |

1.85 |

|

| Machine weight (kg) | 4600 | 5200 | |

| Gross Weight (kg) | 5600 | 6300 | |

| Air Compressor (not included)(hp) | 7.5 | 7.5 | |