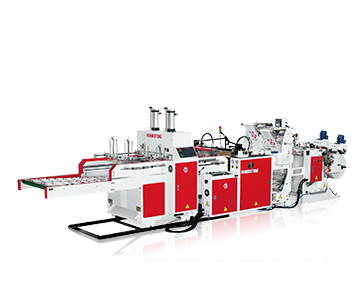

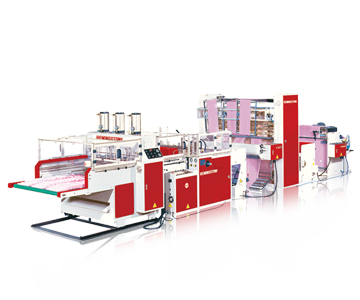

Fully Automatic T-shirt Bag Making Machines

Model: HM-1200V4A

FINISHED PRODUCTS

T-shirt Bag

FEATURES

This machine is automatically controlled by the computer completely. The user can operate it by a colored touch panel.

The computer monitors the operation, and stops the machine immediately whenever any abnormality occurs. The abnormal codes and solutions will be displayed on the touch panel. It helps to reduce the confusion of repair.

This machine can reach the demand of high-speed production. The max production speed for each line is 100 M/min and 250 cycles/min. When the bag width is under 250mm, it can produce with 4 lines of bag films simultaneously. The max production speed can reach 1000 pcs/min.

This machine can produce with the bag width between 100mm~500mm. It can produce 4 lines simultaneously with bag width under 250mm. Its utility and production efficiency are highly enhanced.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-1200V4A | |

| Bag Size (mm) | ||

| Width (mm) |

150~250 x 4 lines 150~500 x 2 lines |

|

| Length (mm) | 260~650 | |

| Max. Production Speed (cycles/min) |

Max.250 100 m/min |

|

| Tension Control | With Blowing Type | |

| Thickness of Film (mm) | 0.01~0.04 | |

| Heaters (kw) | 7 | |

| Power Required (kw) | 11 | |

| Machine Dimensions | L (M) | 8.8 |

| W (M) | 2.1 | |

| H (M) | 1.7 | |

| Machine Weight (kg) | 3300 | |

| Gross Weight (kg) | 3800 | |

| Air Compressor(not included) (hp) | 7.5 | |

Relative Products

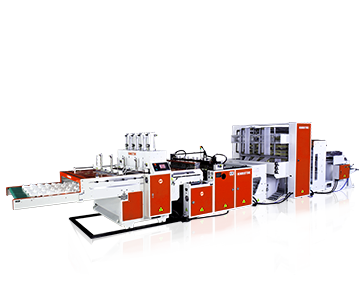

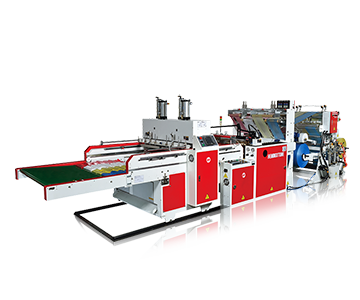

Super High Speed 2 Lines T-shirt Bag Making Machine with Hot Slitting & Servo-Drive System

Super High Speed Fully Automatic 2 Track T-shirt Bag Making Machine

Super High Speed 4 Lines T-shirt Bag Making Machine with Hot Slitting & Servo-Drive System

Fully Automatic T-shirt Bag Making Machines With Dancing Roller Tension Control & 4 Sets EPC Control

Super High Speed Fully Automatic Servo Drive Three Lines Three Rolls T-shirt Bag Making Machine

Super High Speed 3 Lines T-shirt Bag Making Machine With Hot Slitting & Servo-Drive System

High Speed Fully Automatic T-Shirt Bag Making Machine With Servo-Drive