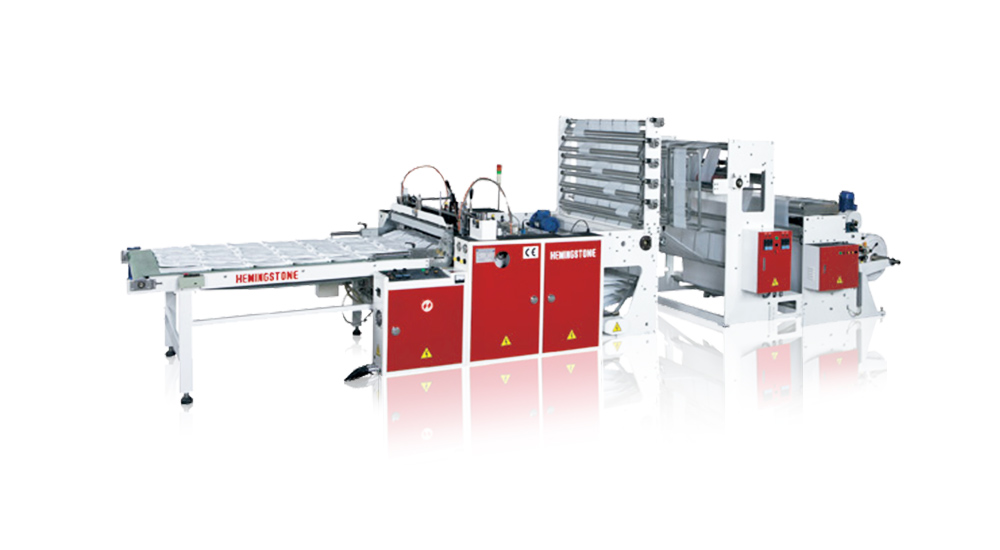

Super High Speed 5 Lines Bottom Sealing Bag Making Machine with Hot Slitting & Servo-drive System(1000 pcs/min)(Non Stop)

Model: HM-1100B5

FINISHED PRODUCTS

FEATURES

This machine can make a big roll into small rolls by using hot slitting. The machine productivity is extremely high.

Suitable to make 1~5 lines hot slitting bottom sealing bags.

This machine can simultaneously produce bottom sealing bags in different bag width.

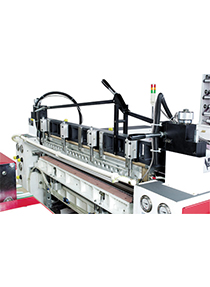

With a fully automatic computer control servo system, this machine can have both a high speed and a stable productivity.

Suitable to produce multi-line printed bottom sealing bags.

Need Help?

Please send your inquiry to your local subsidiary or use our contact form.

Product Inquiry

SPECIFICATIONS

| Model | HM-1100B5 | HM-1100B5G | |

| No. of Tracks(Max.) | 5 | 5 | |

| Film Unwind Width(Max.)(mm) | 900 | 1600 | |

| Film Diameter(Max.)(mm) | 1000 | 1000 | |

| Bag Size(mm) | Width(each line)(min.) | 100 | 100 |

| Length | 250~700 | 200~700 | |

| Production Speed(cycles/min) | 200 | 200 | |

| Thickness of Film(total)(mm) | 0.01~0.03 |

0.01~0.03 |

|

| Film Line Speed Cycles(m/min) | 100 | 100 | |

| Power Required(kW) | 11 | 13 | |

| Machine Dimensions | L(m) | 9 | 11 |

| W(m) | 2.35 | 2.29 | |

| H(m) |

1.94 |

2.2 | |

| Machine Weight(kg) | 2500 | 3200 | |

| Air Compressor(not included)(hp) | 7.5 | 7.5 | |

| Remarks | Without side gusset device | With side gusset device | |